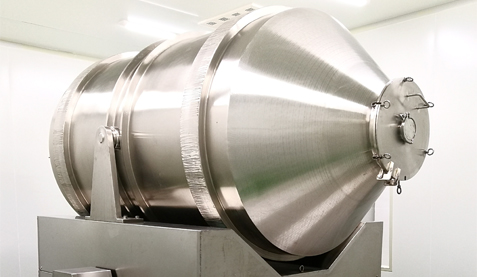

Fumeipharm pharmaceutical excipients wax products workshop introduced advanced Germany filtration, molding and prilling equipment and automatic production control system. Eight 2-tons melting tanks, eight 5-tons buffer tanks, and four 10-tons finished tanks are placed in the new workshop. All tanks pipes and fittings are made of stainless steel, the temperature and weight are controlled by PLC to ensure the accuracy of production, while the internal cleaning system in the tank reduces the risk of cross contamination between batches.

The efficient material pipeline layout provides backflow of the unqualified products and prevents them entering the next process step. Unqualified products are tested out during the production process, they will return directly to the original wax melting tank instead of entering the next process. Wax will return to the melting tank if the impurities content is not qualified after filtration, and the wax will return to the melting tank for further bleaching if the bleached color is not approved by in-process test.

Automatic temperature control system, flowing monitoring system and material online preparation are used to accurately achieve product index and quality stability.

Accurate material flow metering and uniform blending ensure the homogeneous of the finished products quality in the tank.